Expert Answer

Comment

CommentPlease like this answer, so that I can get a small benefit, please

Answer:

A. Decision Variables:

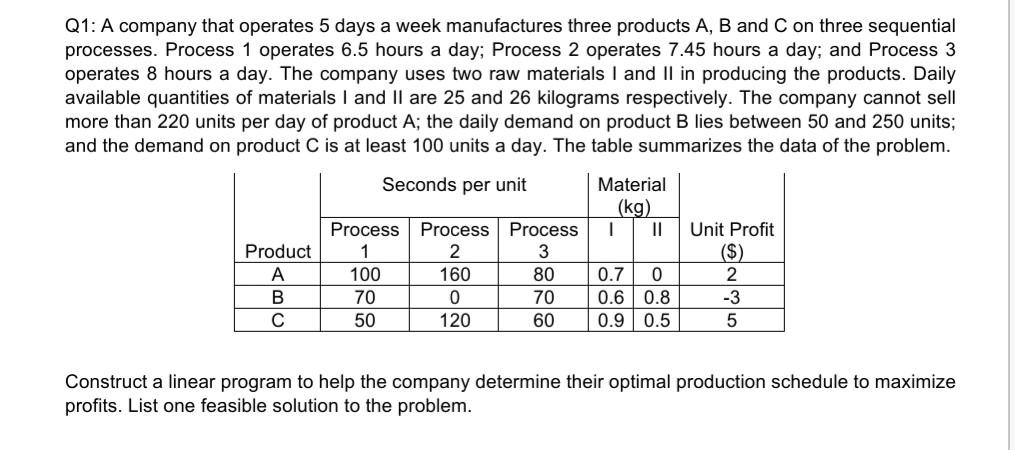

Let a,b,c be the quantities of products A,B & C respectively that need to be produced.

B. Optimization Function :

Since data on per unit profit is available, the profit is to be MAXIMIZED, i.e:

Maximize 2a-3b+5c

C. Constraints:

1. Constraints on demand:

a <= 220 ( since company can't sell more than 220 units per day of product A)

50 <= b <=250 (since daily demand of product B lies between 50 & 250 units per day )

c >= 100 (since demand of product C is atleast 100 units per day)

2. Constraints on process availability:

100a+70b+50c <= 23400 (since process 1 is available only for 6.5 hours or 23400 seconds)

160a+120c <= 26820 (since process 2 is available only for 7.45 hours or 26820 seconds)

80a+70b+60c <= 28800 (since process 3 is available only for 8 hours or 28800 seconds)

3. Constraints on raw material:

0.7a+0.6b+0.9c <= 25 (since daily availability of raw material I is 25 kgs)

0.8b+0.5c <=26 (since daily availability of raw material II is 26 kgs)

4. Non negative constraints:

Since only non-negative units can be produced,

a,b,c>=0

On solving the above constraints by using trial & error / graphical / Solver method in Microsoft Excel, we get optimum production quantity as:

a=0 units

b=50 units

c=100 units

Max. Profit = $350

ليست هناك تعليقات:

إرسال تعليق